All Products

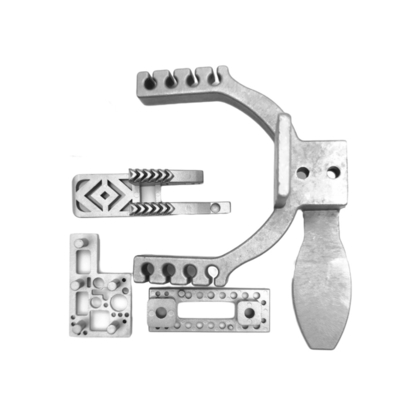

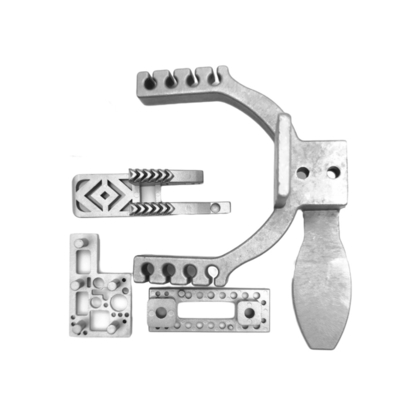

Metal Injection Molding The Best Manufacturing Process for Motor Gear Accessories

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | MDM |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 1000 pieces |

| Price | $0.60/pieces 1000-4999 pieces |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Condition | New | Type | Powder Metallurgy Parts |

|---|---|---|---|

| Spare Parts Type | OEM | Video Outgoing-inspection | Provided |

| Machinery Test Report | Provided | Marketing Type | New Product 2023 |

| Material | Carbon Steel | Plating | NICKEL |

| Warranty | 2 Years | Key Selling Points | High-accuracy |

| Weight (KG) | 0.01 KG | Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Printing Shops, Construction Works , Other |

| Local Service Location | None | Showroom Location | None |

| Process | Metal Injection Molding | Application | Industry |

| Size | Customer's Drawing Required | Lead Time | 30 Days |

| MOQ | 1000pcs | Packing | Poly Bag + Inner Box + Carton |

| Color | Custormer's Requirements |

Product Description

PRODUCT SPECIFICATIONS

Material material | 304L 316L Fe2Ni | Product type | Hardware parts |

Powder pretreatment | Powder annealing | Powder preparation method | Atomization method |

Forming method | Die forming | Mold material | Steel mould |

Mold type | Die | Sintering method | Solid sintering |

Sintering atmosphere | Vacuum | Sintering temperature | 1350-1550 |

Pressing mode | Bidirectional molding | Postprocessing | Heat treatment |

Proofing cycle | 10 to 15 days | Processing cycle | 10 to 30 days |

PRODUCTS DESCRIPTION

FEATURES AT A GLANCE

COMPANY PROFILE

Dongguan Minda Metal Tchecnology Co.,Ltd. Was founded in 2015. We specialize in producing MIM parts, PM part, CNC machining parts and Aluminum alloy, Magnesium alloy and Zinc alloy die casting parts. At the same time we also undertake the corresponding product mold design and development and production. Our professional sales staff will communicate and understand the needs of customers in a timely manner and convey to the technical staff, and the general manager will quickly give the quotation scheme suitable for the product. In the production process, we will check the quality of products at any time. The product will be fully inspected before shipment to ensure that none of the defective products reach the customer's hands. You have the right needs and we have the right expertise, for hardware accessories solutions please feel free to contact us, we are there for you 7x24h.

Our Advantages

Our Partners

FAQ

Q1.Are you a maunfacture or a trading company? A: We are a manufacture & trading company with over 10 years' experience in custom machining service. And have been trading with overseas clients for many years. Q2. How do you work the parts? A: We mainly produce custom parts, means produce according to clients’ drawings or samples. We will fully evaluate the drawings before production and provide customers with the best solution to minimize the costs. Q3. What kind of materials are used on your products normally ? A: .For die-casting process we use Aluminum alloy, Magnesium alloy and Zinc alloy. For MIM/PM process the materials are Iron base, stainless steel powder. For CNC machining parts the materials are Steel 4140, 4340, #45 steel, Chroma steel, 420 SS, 304SS, 316SS, Brass, Titanium etc. Q4.What is the payment term? A: T/T, L/C, D/P, D/A acceptable, just let us know which is convenient for you.

Recommended Products