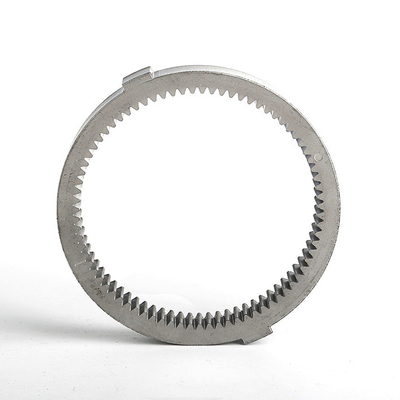

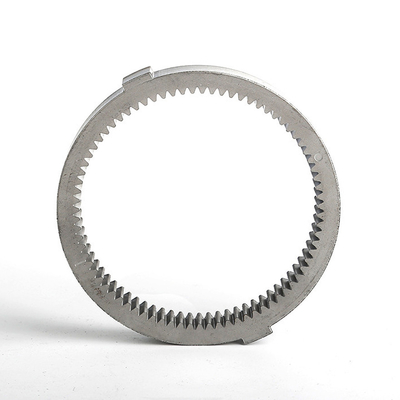

FN08 316L Sintered Metal Parts Processing Straight Bevel Gear Machining

| Place of Origin | China |

|---|---|

| Brand Name | MDM |

| Certification | ISO9001:2015 |

| Model Number | PM002 |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 1000 pcs |

| Price | $0.05~$0.88/piece |

| Packaging Details | PE bag+carton+pallet |

| Delivery Time | 20-30 work days |

| Payment Terms | T/T, Alipay, Paypal |

| Supply Ability | 50000 pcs per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Wide Range Of Applications | Yes | Durability | High |

|---|---|---|---|

| Precision | High | Material | Iron, Steel, Stainless Steel, Brass, Copper Etc. |

| Dimensional Accuracy | ±0.02mm | Strength | Hardness 30-45HRC |

| Corrosion Resistance | Salt Spray Test 72h Min. | Wear Resistance | High |

| Heat Resistance | High | Cost-Effective | Yes |

| Complex Shapes | Yes | Surface Finish | Smooth |

| Density | 7.0g/cm³ | Customizable | Yes |

| Production Process | Sintering | Color | Original, Black, Silver, Shiny |

| Highlight | FN08 Sintered Metal Parts,Sintered Metal Parts Bevel Gear,316L sintered parts |

||

MDM Metal focuses on providing a cost-effective alternative to forging, stamping, casting, and machining processes. It combines the high volume process of powder metal compaction with superior physical properties achieved through high temperature, controlled atmosphere sintering. Full Density Powder Metallurgy combines the high volume processing of powder metal compaction with the physical properties of cast or wrought materials. Full Density provides the ultimate physical properties for conventionally compacted PM materials. High precision and high density one forming tolerance is small, high precision, density up to 90%, and can improve the precision and strength performance through shaping or repressing.

Product Description

| Technology | Powder Metallurgy | Metal injection molding |

| General Material | Fc0208, Fn0208, SMF5040 | 17-4Ph, 4605, FN08, 420SS, 304L, 316L |

| Density | 6.7-6.8g/cm³ | 7.7-7.8 g/cm³ |

| Hardness |

Fc0208(20-30HRC) Fn0208(35-40HRC) |

17-4Ph(35-40HRC) 4605(45-50HRC) |

| Application |

Medical apparatus and instruments, Hardware field, Automobile industry, Home appliances Aerospace industry, Automation field, |

|

![]()

Our Main powder metallurgy products

Advantages of powder metallurgy process

- Q: What materials can you process?

A: Steel 4340,4140, Stainless steel 304, 316, 420, Aluminum 6061, 7075, Brass, Copper, POM, Titanium etc.

- Q: Can you protective my business, will my drawing be safe after you get it?

A:Yes, we can sign the NDA before you send the drawing.

- Q: What type of drawings can you read?

A: We can read STEP, IGS, CAD, PDF, Solid works, etc.

- Q: Do you provide samples?

A: Yes, for the molding parts we can supply free samples. For CNC parts we need to charge for samples and refund when place the mass production order.

- Q: How soon can I get your quotation?

A: Normally 12 hours to 24 hours.

- Q: What's the lead time?

A: 7-30 working days, depends on the order quantity.

- Q: Can you do surface treatment for the products?

A: Yes. We can do heat treatment for iron and steel parts, hardness is 30-60 HRC according to the requirements. And black oxide, electric plating.

PVD coating for stainless steel with black, silver, blue, rose gold and many colors.

For aluminum parts, we can do anodize for different colors.