All Products

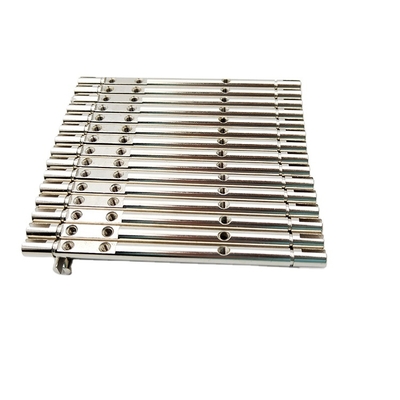

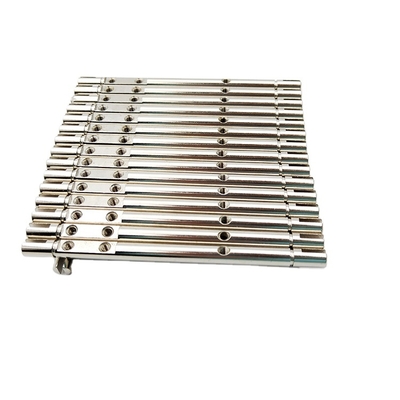

Custom CNC Machined Aluminum Alloy Parts with 0.02mm Tolerance

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | MDM |

| Model Number | MDM |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 1000 |

| Price | $0.37-0.61 |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| CNC Machining | Yes | Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless Steel, Steel Alloys |

|---|---|---|---|

| Micro Machining | No | Material | Aluminum Alloy |

| Surface Treatment | Anodizing | Tolerance | 0.02mm |

| Processing Method | CNC Machining Lathing | Surface Roughness | Ra 0.8-3.2 |

| Technics | CNC Turning/milling/machining/drilling/laser Cutting/stamping/wire Cutting | MOQ | 100 |

| Size | Customized Sizes Acceptable | Color Options | PVD Black/silver/yellow/golden, Black Oxide, Zinc Plating Black/silver/colorful |

| Material Options | Aluminum 6061/7075, Stainless Steel 304/316/420/303, Brass, Copper, Titanium, Carbon Steel, Mild Steel, #45 Steel, 4140, 4340, Kovar Alloy | Surface Treatment Options | Zinc Plating, Chrome Plating, Nickel Plating, PVD Coating, Anodizing, Polishing, Sand Blasting |

| Quality Control | 100% QC Inspection | ||

| Highlight | custom CNC machined aluminum parts,high precision CNC machining parts,aluminum alloy CNC parts with warranty |

||

Product Description

OEM Stainless Steel Aluminum CNC Machining Custom Parts

Product Specifications

| Attribute | Value |

|---|---|

| CNC Machining or Not | CNC Machining |

| Type | Broaching, Drilling, Etching/Chemical Machining, Laser Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless Steel, Steel Alloys |

| Micro Machining | Not Micro Machining |

| Material | Aluminum Alloy |

| Surface Treatment | Anodizing |

| Tolerance | 0.02mm |

| Application | Machinery |

| MOQ | 100 |

| Packing | Poly Bag + Inner Box + Carton |

| Quality Control | 100% QC Inspection |

| Size | Customized Sizes Acceptable |

| Color | Customized Colors |

| Processing Method | CNC Machining Lathing |

Product Details

| Material | Aluminum 6061/7075, Stainless Steel 304/316/420/303, Brass, Copper, Titanium, Carbon Steel, Mild Steel, #45 Steel, 4140, 4340, Kovar Alloy |

| Surface Treatment | Original or customized options including zinc plating, chrome plating, nickel plating, PVD coating, anodizing, polishing, sand blasting |

| Technics | CNC Turning, Milling, Machining, Drilling, Laser Cutting, Stamping, Wire Cutting |

| Sample Policy | Sample costs refundable upon mass production confirmation |

| Surface Roughness | Ra 0.8-3.2 |

| Color Options | PVD black/silver/yellow/golden, black oxide, zinc plating black/silver/colorful |

| Quality Assurance | 100% inspection before shipping, 2-year sales guarantee |

Company Profile

Dongguan Minda Metal Technology Co., Ltd. was founded in 2015. We specialize in producing CNC machining parts, MIM parts, powder metallurgy parts, and aluminum/magnesium alloy die casting parts. We also undertake corresponding product mold design, development, and production.

Our professional sales team communicates with customers to understand requirements and convey them to technical staff. The general manager provides quick quotations tailored to product needs.

During production, we conduct continuous quality checks. All products undergo full inspection before shipment to ensure zero defects reach customers.

For hardware solutions, contact us anytime - we're available 24/7.

Packaging & Shipping

Frequently Asked Questions

Q1. What kind of documents do you need for a quotation?

A: We need PDF drawings, 3D drawings files in STEP, IGS or X_T format.

Q2. Can you make the parts according to samples?

A: Yes, we can. You need to send us samples for assessment. We can create drawings from physical samples for production.

Q3. What kind of materials are used on your products normally?

A: Aluminum, Steel, Brass, Stainless Steel, Bronze, Titanium alloy, etc.

Q4. Can you assemble the products?

A: Yes. We can assemble products according to customer assembly drawing requirements.

Recommended Products